Field Experience Using Trak Joints

A New Method to Install Contraction Joints

A new method to install contraction joints in slabs-on-ground offers speed and cost advantages over existing methods. Even silica dust concerns are eliminated. Joints are installed in fresh concrete, which is earlier than early-entry saw cuts, so the occurrence of random cracks is reduced. Denny Janeway with Platinum Construction builds residential slabs-on-ground in California. He said, “We put Trak Joints at 10 ft. and have great success in minimizing random cracking.”

Trak Joints cost one-fourth that of saw cut joints. The installed cost of Trak Joints is $0.15/l.f. In comparison, saw-cut joints cost a minimum of $0.60/l.f., and zip strips $0.30/l.f. Eliminating silica dust makes the economic advantage even greater.

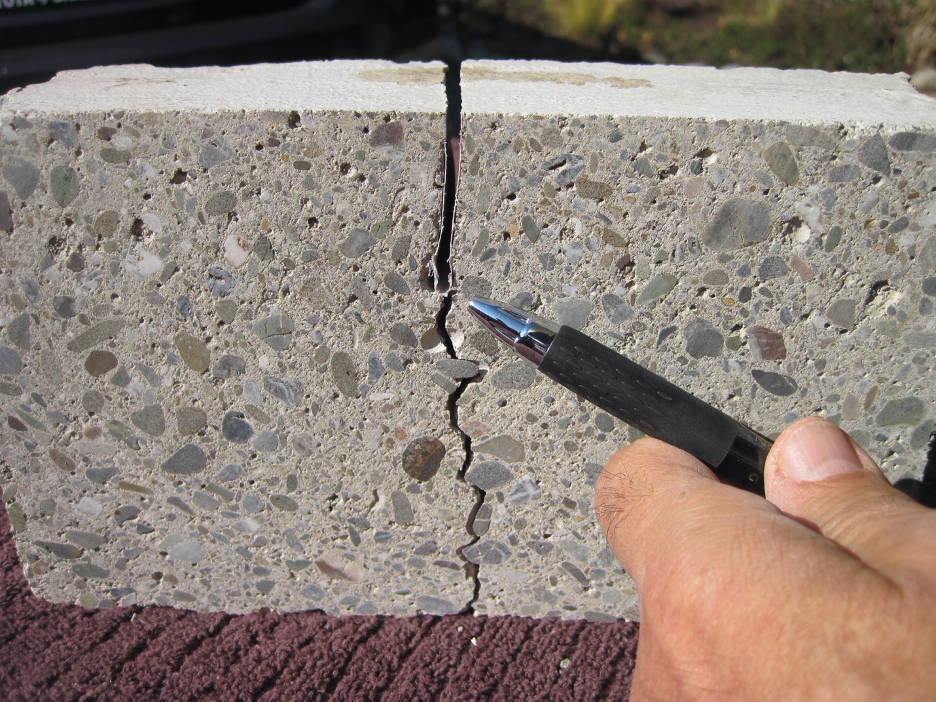

Trak Joints are installed using a manually operated tool, called the Traker, to embed a strip of polymer tape into fresh concrete. The tape remains in the slab to create the weakened plane. Slab finishing operations are performed over the embedded tape. The final appearance of Trak Joints depends on the depth of concrete cover over the top of the embedded tape. When the top of the tape is located right at, or close to, the surface of the slab, the final appearance of Trak Joints is a relatively straight line in the concrete. If the top of the tape is further down in the slab, the crack can appear jagged, but still relatively straight.

Applications for Trak Joints are for slabs or pavement where this kind of joint appearance is acceptable. Residential house slabs usually receive floor coverings, so this application is ideal. Slabs containing radiant heating tubes are another useful application where the possibility of a saw blade nicking a tube is eliminated. Utility slabs, farm shed slabs, small commercial building slabs, strip malls, multi-family housing, and parking lots are other applications. In the pavement field, Trak Joints can be used in lean concrete bases and city/county roads.

When used in roads, an advantage is minimizing rainwater entry into the joints, where flooding the sub-base area can create pumping problems. The tape prevents rainwater from getting to the base. When residential slabs are exposed to weather, the tape also keeps the base dry. This is important in minimizing later problems with water vapor emissions under floor coverings.

Contraction joints from 1 to 2 inches deep can be installed by the Traker. This relates to slabs 4 to 8 in. thick. The depth of the insertion disc is adjustable to allow for the different contraction joint depths.

An innovative part of the method involves the tape being folded as it is embedded into the concrete. When the Traker is in operation, a roll of tape rides on an insertion disc. As the Traker moves forward across a slab, friction between the insertion disc and concrete causes the disc to rotate. A strip of tape is spooled off the roll and folded as it is embedded into the concrete. The final joint has proper depth and vertical orientation.

To its benefit, the width of Trak Joints is narrow after drying shrinkage occurs. General knowledge is that concrete slabs experience shrinkage of 1/8 in. for slab sections 20 ft. long. If joint spacing is 10 ft, then each joint would open 1/16 in. wide. In contrast, saw cuts are typically the width of the diamond blade at 1/8 in. plus the shrinkage amount at 1/16 in., for a total 3/16 in. If joints are to be filled with epoxy or polyurethane, far less material is needed to fill the Trak Joints.

Lessons learned from field experiences are informative. The following discussion highlights some field experiences. During slab construction, Trak Joints need to be installed while the concrete is highly workable. In cool weather, finishers can wait an hour or more after bullfloating the surface and before installing the joint. In hot weather, however, experience has shown that the joints need to be installed within one-half hour after concrete placement. Beyond this time period, the aggregate particles settle into position, and it then becomes difficult for the insertion disc to push the aggregate aside. The top ½ inches of the concrete can still be highly workable, but deeper down the coarse aggregate particles resist movement. If this occurs, the insertion disc rides up and over the aggregate, which causes the tape to extend above the surface of the slab. Visual feedback is immediate that the concrete is too firm.

If this occurs — and it seldom happens once the finishers learn when they need to perform the various operations — just pull the tape out of the concrete. Remove the roll of tape from the Traker. Run the Traker through the concrete with back and forth motion, which creates a groove of proper depth. Now, the tape can be installed by the Traker.

The Traker is factory set to fold tape off center by 1/8 in., which causes the tape at its free edges to be ¼ in. higher on one side. Any tape that extends above the surface of the slab will be a single layer of tape. The Traker is built to ride over reinforcing bars that are located high in the slab. At the front of the tool is a pivot, which allows the insertion disc to raise by an inch. When the insertion disc lifts, the tape itself will lift and will show at the surface. Tape extending above the concrete surface can be easily removed. The following day or later, use a handheld propane touch to melt the exposed tape. This operation goes quickly.

Joints go in slabs from both directions, i.e., east-west and north-south. When the Traker crosses a newly installed strip of tape, the insertion disc pushes down the first strip of tape and installs the second strip above it.

The Traker gets pushed by a long handle pole of up to 30 ft. from one side of the slab and can be pulled an additional 30 ft. from the other side. A rope can be attached to the Traker to pull it when distances are greater than 30 ft.

In summary, Trak Joints are easy to install in fresh concrete. These early entry joints lower the risk of random cracks. Hazardous silica dust is not produced. The cost is much lower than other methods like saw cutting or inserting rigid plastic strips. Contractors that install Trak Joints have a competitive advantage with lower costs and fewer call backs due to random cracks in slabs.